Subscribe to our quarterly sustainability newsletter today!

Stepan Company Makes Strides Toward Sustainable Water Management at Three Major Manufacturing Sites

April 27, 2022

Stepan Company believes strongly in managing water resources in a way that respects the communities in which we operate and helps ensure that water resources remain abundant for future generations. As a signatory of the United Nations Global Compact, Stepan supports specific targets of the UN’s Sustainable Development Goals (UN SGDs) for which we can have a significant positive impact, such as clean water and sanitation; responsible consumption and production; and climate action.

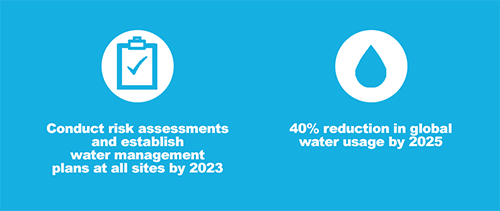

We have set ambitious goals around water conservation to help us support these goals:

So far, Stepan has made significant progress toward these goals. In 2021, we achieved our goal of conducting water risk assessments at all sites two years early. Water risk assessment results were used to risk-rank each site based on the World Resources Institute’s Aqueduct model and were validated using a site-specific survey developed by Stepan. This work puts us on track to achieve our goal of developing water management plans for all sites by 2023.

We also continued to work toward our goal of 40% reduction in water usage by 2025. In 2021, we reduced water use by 30% across our sites initially evaluated in 2016. Several sites demonstrated notable water use reduction, including our sites in Manizales, Colombia; Maywood, New Jersey; and Winder, Georgia.

Circular Economy Through Gas Return

Through the evaluation of wastewater stream management, the team at the Manizales site identified an opportunity to promote circular economy by returning exhaust gas from our site’s operations back to an industry partner in the area to be reused as a raw material. The project resulted in the reduction of wastewater generated at the site by more than 60% and contributed to a significant reduction in water consumption.

“Stepan’s Manizales team has demonstrated a high level of environmental commitment through the gas return project that supports circular economy,” says Nicolas Rodriguez, Manizales Plant Manager.

1.8 Billion Liters of River Water Saved

The water conservation efforts at our Maywood, New Jersey, site have been part of a multi-year plan to shift away from the use of river water as a cooling source to a variety of alternative recirculating systems. The shift to cooling tower water and cold oil cooling has resulted in a use reduction of 1.8 billion liters of river water annually and puts the site on track to eliminate 100% river water use by the end of 2023.

John Ostroski, Engineering and Maintenance Manager at Stepan’s site in Maywood, who has been responsible for identifying, developing and implementing several water reduction projects commented, “I think most would agree that safety is a top priority when designing or developing a process. However, engineers also have the responsibility of ensuring that the process is sustainable — otherwise it is not a true solution. Over the last few years, I have been part of a shift at Stepan that drives greater alignment in this responsibility and continuously assesses our impact on the environment. This change is empowering our current workforce and attracting new talent. The company’s vision on sustainability is one that I think everyone here is proud of.”

Reducing, Reusing and Recycling Steam Condensate

The team at our site in Winder has been working on a steam condensate recovery project which has enabled the reuse of condensate from the site’s operations and reduced our freshwater usage at the facility. This project has also allowed us to reduce the amount of water we send out of our facility as wastewater for treatment. The steam condensate recovery project has been focused on reducing contaminants in the condensate allowing it to be recycled into the site’s steam boiler and eliminating leaks or discharge outside of the condensate system. The project has resulted in reduced water flow to the onsite wastewater treatment plant that consequentially reduces the amount of water discharged from the plant, water chemical treatment costs and helps ensure compliance to environmental permits. It has also helped reduce the amount of energy required to make steam.

This year the team at Winder plans to continue to improve our condensate system by implementing water contamination monitoring equipment that will enable them to quickly identify the source of contaminated water and correct the issue so the water can be recycled.

“The water use reduction project has been a game changer for the site. Not only is it the right thing for our community and the environment, but it also provides the margin to operate the wastewater treatment plant well within our permit limits, even when we treated higher volumes of water generated by storms or increased production from the plant,” said Bobby Poage, Winder Plant Manager.

When asked how the Winder site made significant progress in reducing water usage, Adam Chabayta, Utilities Operator, commented, “[The water use reduction project at Winder] happened because we care. We had support [from the organization] for the project and spent a lot of time and effort in tracking down water and contamination sources that were preventing us from recycling condensate.”

At Stepan we understand the risk and impact associated with water usage and availability around the globe. “These projects are excellent examples of Stepan living up to one of its core values — sustainability. In each case, we evaluated how we were using a critical natural resource and took action to reduce our impact on the environment and surrounding communities. We continue to review site operations for further water reductions and other opportunities to improve our overall environmental footprint,” said Kendall Wilson, Environmental Director.

Across our regions, we look for opportunities to implement efficiency measures to conserve water and reduce wastewater production. In water-stressed areas where Stepan operates, water consumption is strictly managed and initiatives such as repurposing wastewater are utilized. To raise awareness, we have spent the last few years working to better understand water risks and opportunities to further reduce our global water footprint.

Learn more about our sustainability priorities

Visit our sustainability webpage for our sustainability goals